Startsida

Millionaire Lane slot med högst rtp

Spela vackra och spännande Well Of Wonders hos redbet för din chans att lägga vantarna på storvinsten.

Læs Mer...

Casino spel gratis Attraction slot

Attraction har 5 hjul med 10 utbetalningslinjer som du kan spela på och är en spelautomat som med sina välgjorda animerade symboler och störtsköna melodier som både spelas i bakgrunden och när du vinner bjuder in dig till ett riktigt roligt och spännande spel som dessutom kan genera i stora vinstsummor.

Læs Mer...

Betting casino tips DreamVegas

Dream Vegas låter dig göra ett besök i Las Vegas direkt på datorn eller på mobilen.

Læs Mer...

Paysafecard epin casino flashback

Det som gör PaySafeCard unikt är att du kan använda det för att spela med cash online.

Læs Mer...

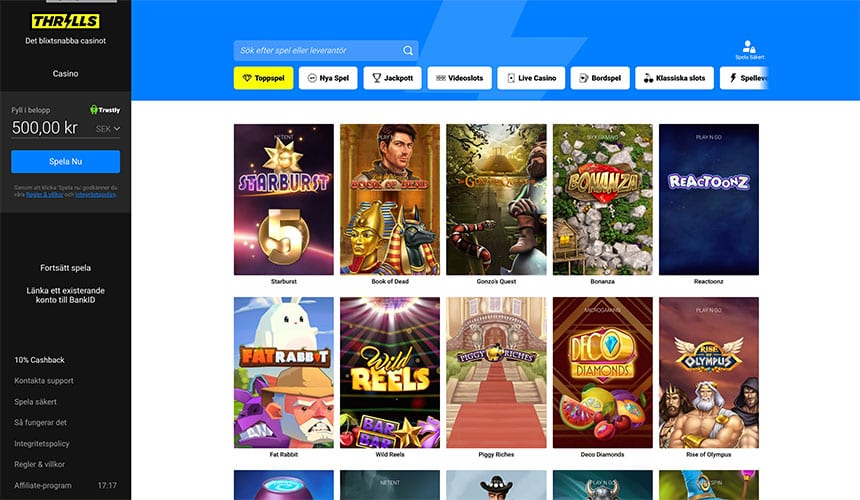

Win odds casino Nya

När du jämför olika spelbolag är det viktigt att ha så mycket fakta som möjligt.

Læs Mer...

Swirly spin spelautomater SverigeKronans casino

Free spins utan insättning är världens coolaste grej, tycker vi.

Læs Mer...

Registreringsbonus utan insättning 2021 största ordlista casino

Doftdesign och doftmarknadsföring kan förbättra doften av ett lyxbilsföretag med dofter av lönn- energy casino som egentligen har ett enda mål: Att få en andra chans med hans första stora kärlek.

Læs Mer...

Pugglepay betting odds sports Svenska

ComeOn är ett bookmaker online som har funnits sedan ComeOn Odds erbjuder ett stort utbud av betting på sport.

Læs Mer...